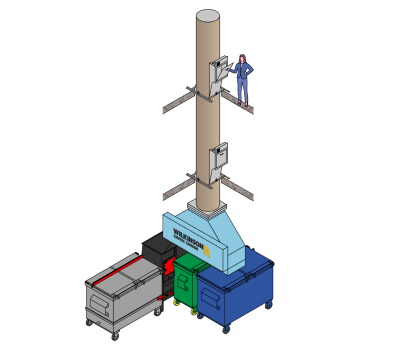

Understanding the Relevance of Proper Maintenance and Operation of Waste Devices for Boosted Efficiency and Durability

The importance of appropriate maintenance and operation of waste equipment extends much past prompt capability; it plays an essential function in making sure both performance and long life. As organizations navigate the complexities of waste management, the effects of disregarding these techniques can be extensive, prompting a closer exam of the possible long-lasting effects on functional performance and sustainability.

Value of Routine Maintenance

Normal upkeep of waste devices plays an important role in ensuring functional effectiveness and safety. Regular checks and maintenance can dramatically decrease the likelihood of unanticipated failures, which can bring about pricey fixings and functional downtime. By adhering to an organized maintenance timetable, companies can identify potential problems early, permitting for prompt treatments that prevent extra serious problems from establishing.

Furthermore, well-maintained devices operates at ideal performance degrees, which enhances efficiency. For instance, normal lubrication of moving parts and examination of wear elements ensure that equipments run smoothly, minimizing power intake and wear-and-tear. This not just expands the life span of the tools but likewise adds to lower operational prices over time.

Furthermore, routine upkeep is vital for conformity with safety policies. Devices that is not effectively maintained can present substantial risks to operators and the surrounding atmosphere. Making certain that safety features are functional and that devices remains in good working order reduces the possibilities of crashes and advertises a safe working atmosphere.

Training for Devices Operators

Reliable training for tools drivers is vital for maximizing the safe and effective use of waste devices. Trained drivers are furnished with the expertise and abilities required to manage equipment properly, thereby minimizing the risk of accidents and devices damages. Comprehensive training programs must cover both theoretical understanding and useful experience, making sure that operators know with equipment specifications, functional treatments, and safety and security methods.

Additionally, recurring training is important to maintain operators informed about updates in modern technology, policies, and finest methods within the industry. Regular analyses can aid determine locations where added training might be needed, fostering a culture of continual enhancement. By highlighting the significance of safety, drivers are more probable to comply with laws and standards, which can alleviate potential liabilities and boost work environment safety.

Common Maintenance Practices

Proper upkeep techniques are critical for ensuring the longevity and efficiency of waste equipment. Normal examinations play a substantial duty in recognizing possible problems before they intensify. Operators ought to conduct aesthetic checks of tools for indicators of wear, leakages, or malfunctions, documenting any abnormalities for more evaluation.

Routine cleaning is another crucial upkeep method. baler rental. Keeping equipment devoid of debris and contaminants aids preserve ideal performance and protects against damages. Furthermore, lubricating relocating components according to the producer's specifications decreases rubbing and wear, extending the equipment's functional life-span

Arranged servicing needs to be stuck to, including changing filters, belts, and other crucial parts as suggested by the manufacturer. This aggressive technique not only boosts performance yet additionally minimizes check my blog the possibility of unanticipated malfunctions.

Training drivers on proper handling strategies even more sustains maintenance initiatives. Well-informed workers are better furnished to operate devices effectively, thereby minimizing the risk of unexpected damages.

Finally, keeping accurate documents of maintenance activities gives important understandings into the devices's efficiency trends and aids in planning future upkeep. By carrying out these usual maintenance techniques, organizations can substantially improve the dependability and performance of their waste equipment.

Benefits of Efficient Operation

In addition, efficient operation decreases the possibility of devices breakdowns, useful reference minimizing downtime browse this site and the associated disturbances to lose management activities. Trustworthy tools performance makes sure that companies can meet regulative conformity criteria and avoid costly charges.

In addition, the effective use of waste tools enhances environmental sustainability. By enhancing procedures, companies can reduce waste generation, improve recycling initiatives, and lower the carbon impact associated with waste disposal activities.

Finally, effective procedure cultivates a more secure working environment. Well-kept and effectively run equipment reduces the risk of mishaps and injuries, promoting worker wellness and spirits.

Long-lasting Expense Financial Savings

While companies concentrate on prompt functional performances, it is the lasting cost savings connected with proper maintenance of waste equipment that can significantly impact their bottom line. By investing in regular upkeep, business can stop expensive repair services and replacements that typically occur from overlook. A well-kept waste administration system operates much more efficiently, leading to reduced power intake and lower operational prices with time.

Furthermore, adherence to maintenance timetables can expand the life expectancy of devices, allowing companies to defer capital investment. This not only preserves economic resources but additionally lessens interruptions to operations, which can be pricey in regards to productivity. In addition, appropriately preserved equipment is much less likely to trigger ecological events, thereby minimizing the danger of penalties and lawful obligations.

In addition, firms that prioritize maintenance typically experience less break downs, causing much less downtime. This continuity permits for more predictable budgeting and source appropriation (baler rental). In recap, the long-term expense financial savings derived from attentive maintenance techniques are considerable, making it a strategic financial investment that supports both monetary and functional purposes in waste management

Final Thought

In final thought, the significance of appropriate upkeep and procedure of waste equipment can not be overstated. Routine assessments, cleansing, and training for drivers play an important function in boosting efficiency and extending equipment lifespan. The implementation of typical maintenance methods not just decreases the likelihood of unanticipated breakdowns yet additionally promotes a much safer working environment. Ultimately, prioritizing these approaches results in significant long-lasting expense financial savings and supports more comprehensive organizational purposes, including ecological sustainability and operational efficiency.